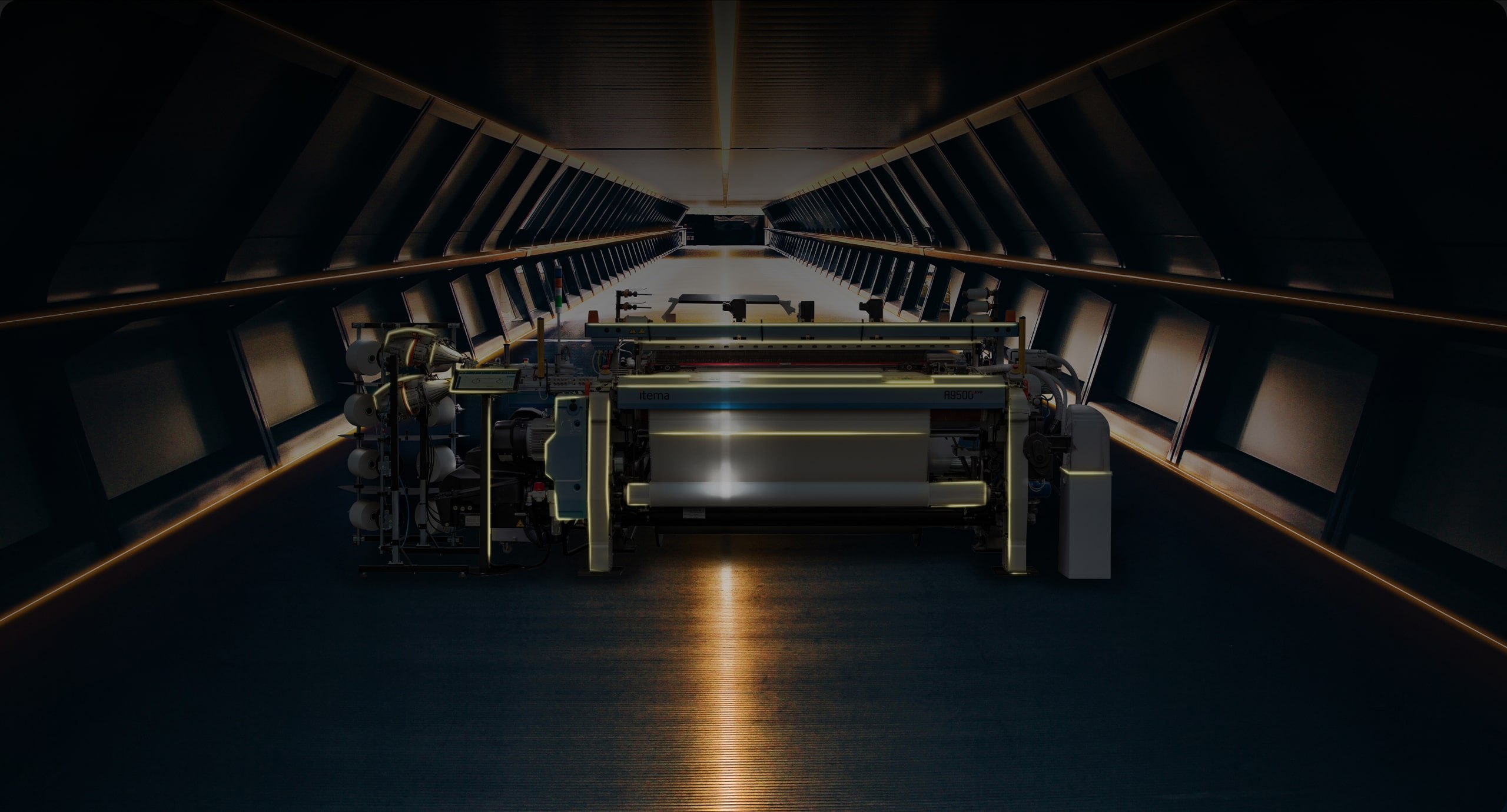

Combining the highest speeds with perfect weft insertion and maximum components reliability is no longer a dream. The A9500EVO comes fully loaded with Itema’s premium innovations that set a new benchmark in air-jet weaving.

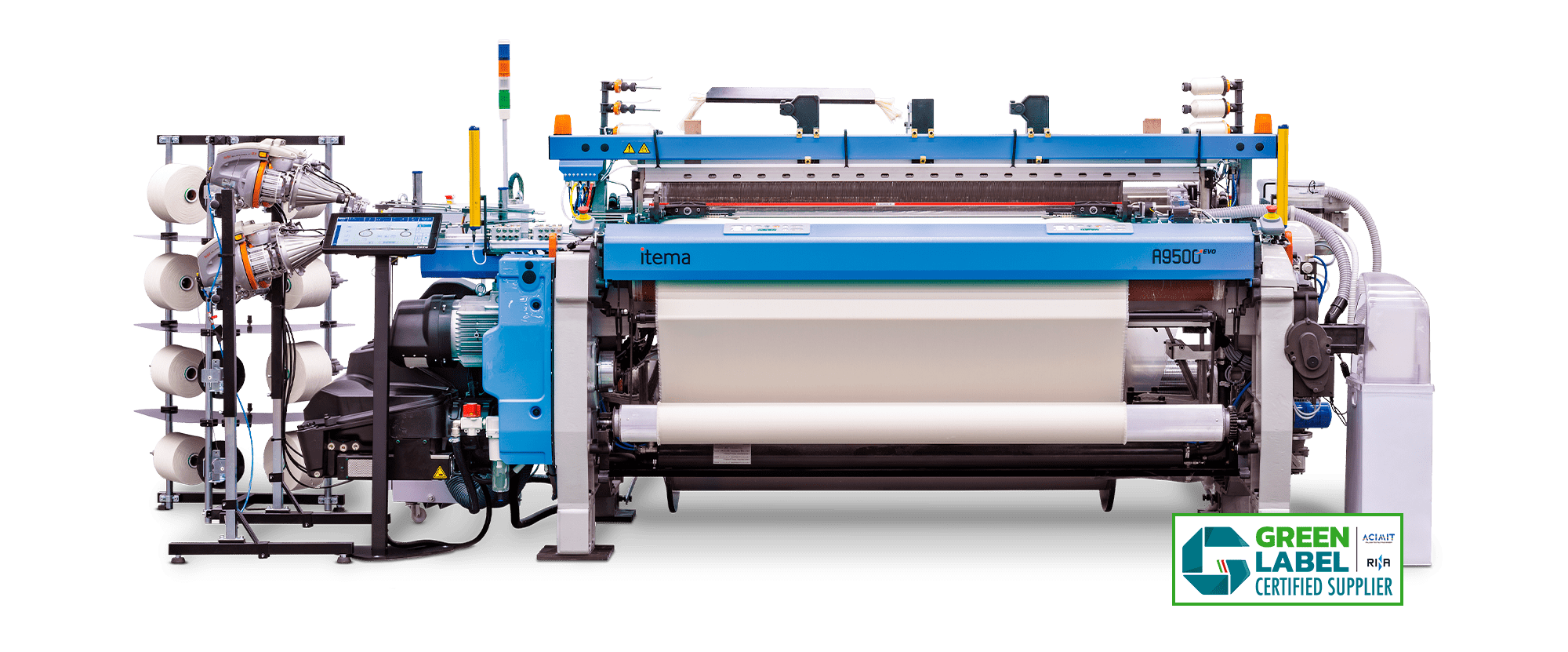

Textile mastery is the real added value of the A9500EVO: Itema engineers focused in further improving the beating heart of the Itema air-jet technology. As a result, the new Itema EVO Pneumatic Platform ensures a full control of the weft insertion. The Itema best-in-class shed geometry is here supported by innovative nozzles to ensure unmatched fabric quality and textile versatility.

Saving is guaranteed by iREED®, the Itema patented reed tunnel shape and position of the relay nozzle which optimizes the air flow in the reed channel for a higher efficiency weft insertion. The Itema patented software iRTC enables the ideal monitoring of the weft insertion cycle guaranteeing reduced air consumption and overruling of incorrect settings.

The Itema iFAR – Filling Automatic Repair – provides automatic repair of short picks and restart of the machine, reducing machine downtime. Finally, the SKYFRAME heald frames ensure maximum reliability even when running at the highest speeds.

Itema A9500EVO: maximum productivity without compromising on fabric quality and user experience.

EVO Pneumatic Platform

Weft Photocells for Full Width Reed

Best-In-Class Itema Shed Geometry

Bi-Power Stretch Nozzle

EVOConsole

iFAR

iRTC

Double Tandem Nozzles

ACIMIT Green Label Certified

EVO Main Nozzles

Itema Heald Frames

New Front Cover with Integrated Pushbutton Panels