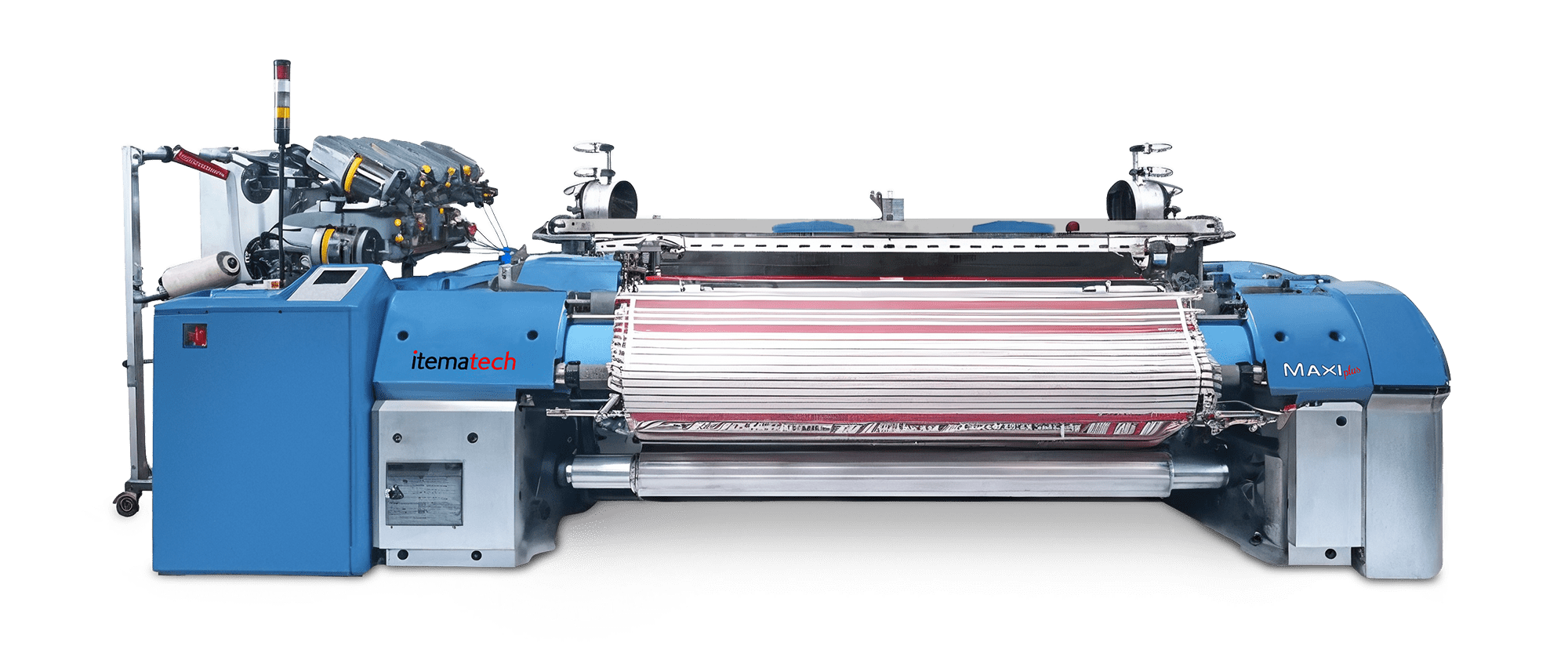

Flexibility, consistent performance, reliability and outstandingly easy to use are the qualities that make MAXIplus the perfect machine for modern weaving.

Easy to run, MAXIplus is the epitome of continuous improvements that made possible the weaving of a range of numerous fabrics.

The MAXIplus distinguishing element is the weft transportation system that makes it possible to exchange between negative and positive rapier.

This characteristic is a guarantee of success in the weaving of different articles in terms of weight and density, and it makes it possible to reach a superior operating flexibility thanks to the simplification of the textile regulations.

It is especially appreciated to weave different textures in the clothing and furnishing sectors, but also in the agriculture and geotextile sectors, where its winning versatility can really be seen both for light and heavy technical fabrics. MAXIplus guarantees excellent results in terms of cost/performance and quick return on investment..

MAXIplus is also available in a various range of weaving widths, for example in nominal widths of 5500mm and 6200mm.

MAXIplus: an efficient partner for modern weaving.

Exclusive Positive and Negative Weft Transfer

Exclusive Shed Geometry

Effective Weft Yarn Selector

Smart Weft Cutter

Direct Drive Technology

Armotion Independent Motor for the Shedding Machine

User-friendly Machine Console

Remote Diagnostics